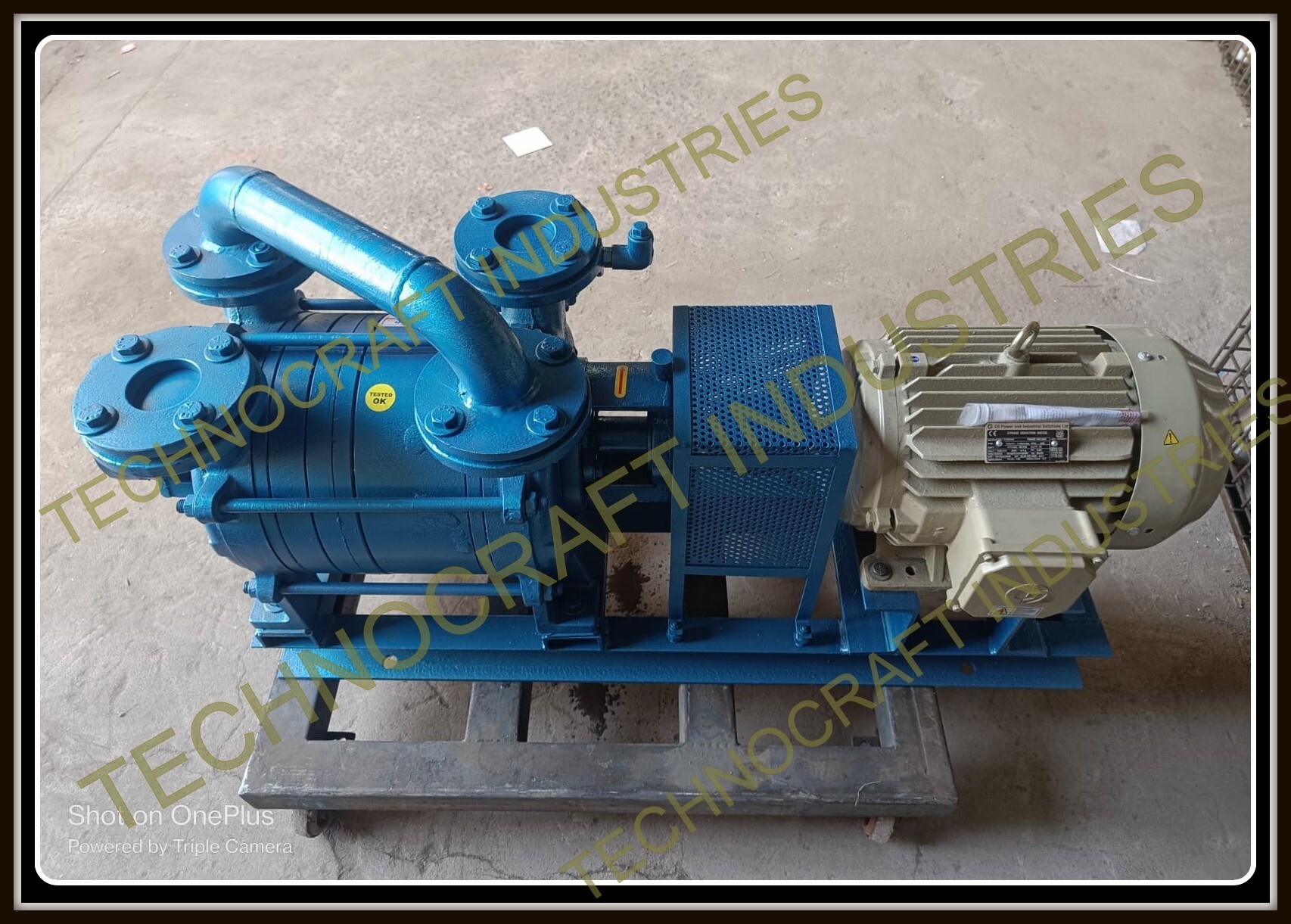

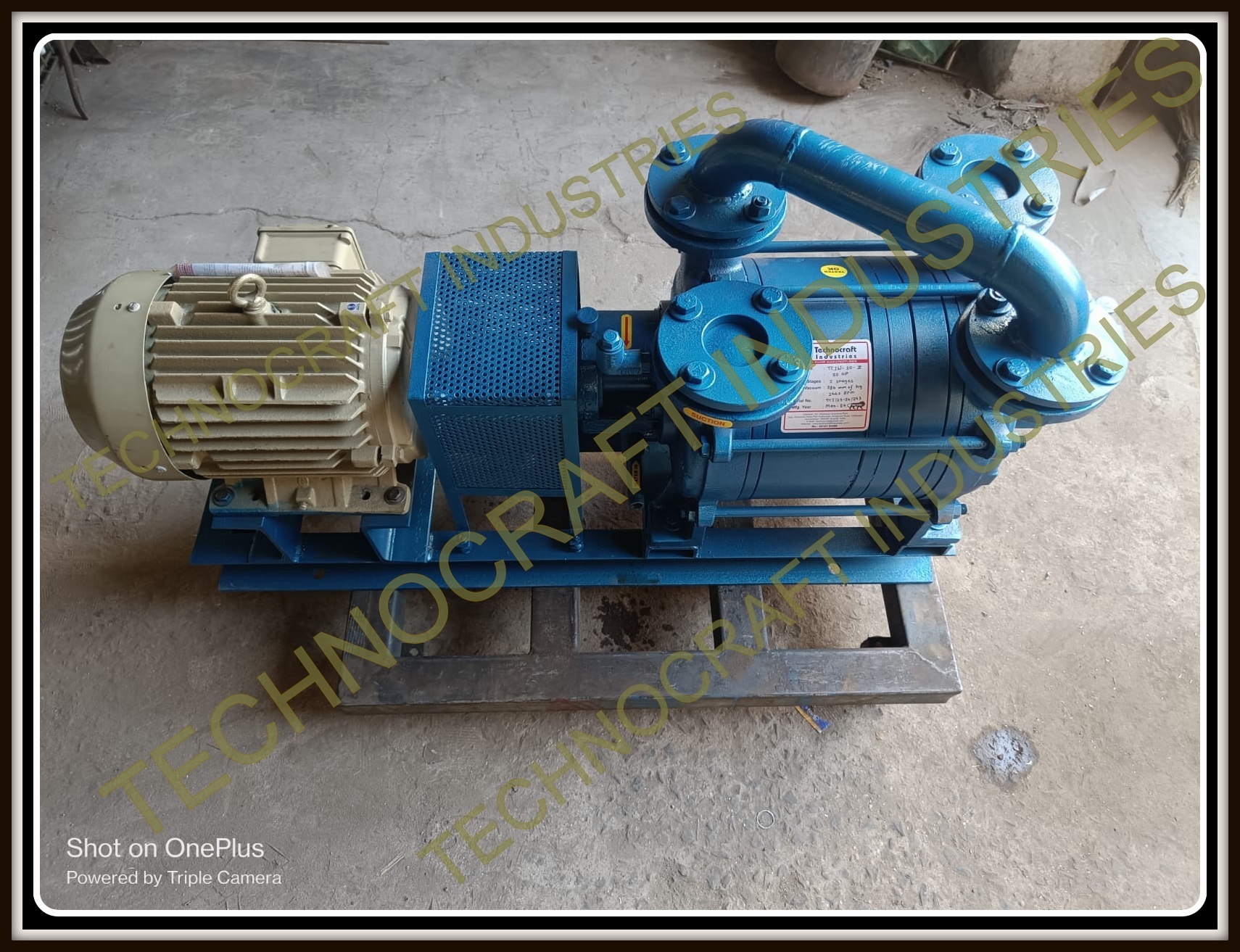

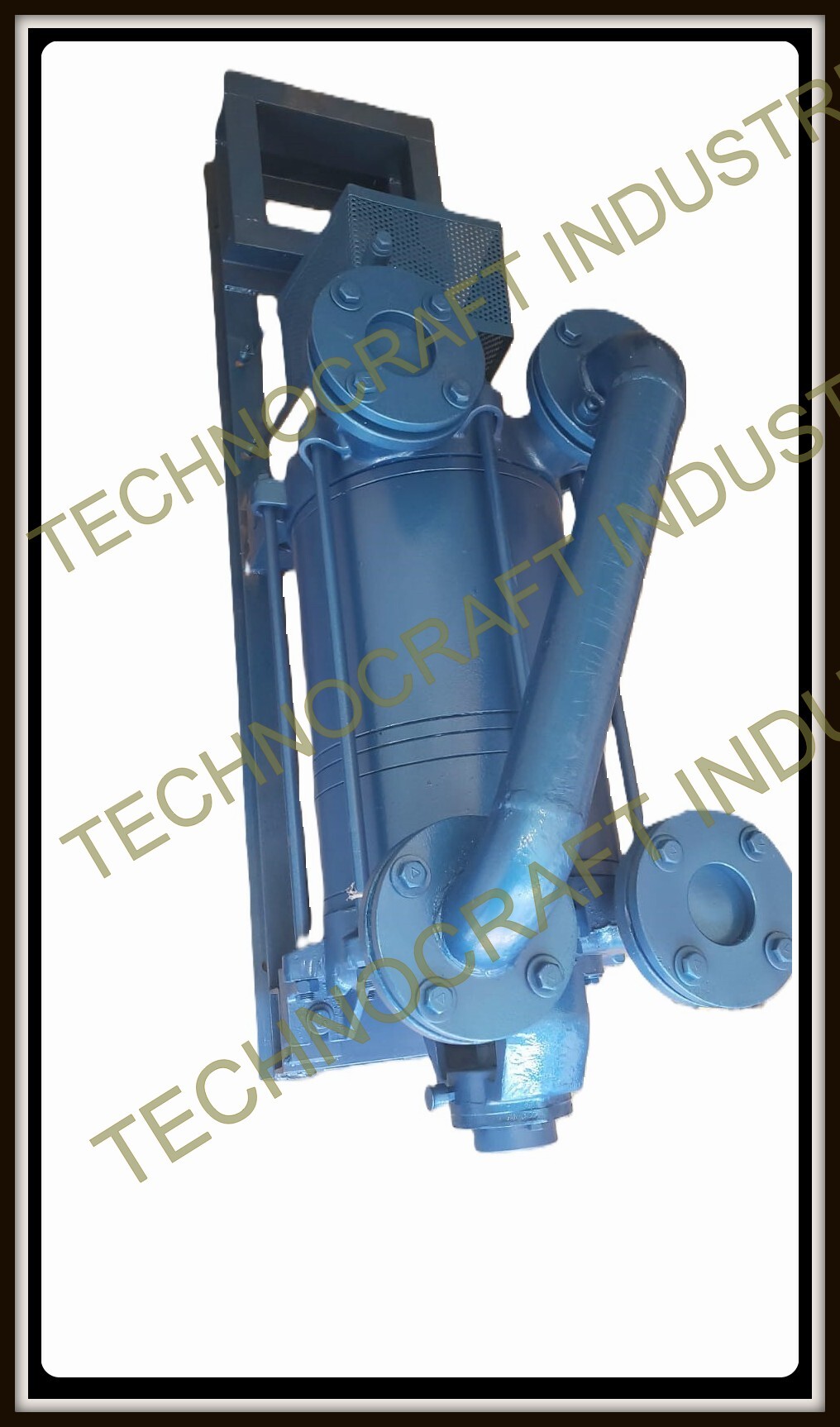

Two stage water vacuum pump

Two stage water vacuum pump Specification

- Flow Rate

- 85 m/hr to 1080 m/hr

- Theory

- Vacuum Pump

- Inlet/Outlet

- Standard as per our specific design

- Max Suction

- 760 mm of hg

- Usage

- Draining Paper webs, Evacuting Condensers and Piping Priming Pumps & Drying resins, Paints and chemicals. Conveying wheat, Sugar& Chemicals Products,

- Material

- Cast Iron, SS-304, SS-316, Bronze, Gun Metal & as per process requirement

- Size

- Different Available

- Power

- Electric

- Product Type

- Two stage water vacuum pump, Water ring type vacuum Pump, Direct couple vacuum Pump, Liquid ring vacuum Pump, High Vacuum Pump , ring vacuum Pump

- Color

- Blue

- Seals Type

- Mechanical Seal and Gland Packing

Two stage water vacuum pump Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD)

- Delivery Time

- Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Two stage water vacuum pump

The Two Stage Water Vacuum Pump is a highly efficient industrial solution designed to handle diverse applications such as draining paper webs, evacuating condensers, drying resins, paints, and chemicals, as well as conveying products like wheat, sugar, and chemicals. Powered by an electric mechanism, this vacuum pump combines precision and durability, built with versatile material choices including cast iron, SS-304, SS-316, bronze, and gun metal to suit specific process requirements. With a flow rate ranging from 85 m/hr to 1080 m/hr and a maximum suction capacity of 760 mm of Hg, it provides outstanding performance across demanding tasks. Designed with standard inlet/outlet configurations tailored to specific needs, it comes equipped with reliable mechanical seals and gland packing to ensure leak-free operation. Available in varying sizes and featuring a robust blue finish, the pump is ideal for industries requiring optimized and efficient vacuum operations.

FAQs of Two stage water vacuum pump:

Q: What are the main applications of the Two Stage Water Vacuum Pump?

A: It is used for draining paper webs, evacuating condensers, piping priming pumps, drying resins, paints, and chemicals, and conveying products like wheat, sugar, and chemicals.Q: What material options are available for this pump?

A: The pump can be made from cast iron, SS-304, SS-316, bronze, gun metal, or customized materials as per process requirements.Q: What is the maximum suction capacity of this pump?

A: The maximum suction capacity is 760 mm of Hg.Q: What is the flow rate for the Two Stage Water Vacuum Pump?

A: The flow rate ranges from 85 m/hr to 1080 m/hr.Q: What type of sealing mechanism is used in the pump?

A: It uses mechanical seals and gland packing for effective sealing and leak prevention.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Liquid Ring Vacuum Pumps Category

Cast Iron Two Stage vacuum pump

Price 40000 INR / Piece

Minimum Order Quantity : 1 Number

Inlet/Outlet : Standard as per our specific design

Flow Rate : 85 m/hr to 1080 m/hr

Theory : Vacuum Pump

Usage : Chemical Industry, Pharmaceutical Industry, Sugar & Distillary Industries, Plastic Industries, Packaging Industries, Ceramic Industry, Power Industry, Paper & Pulp Industry, Environment Industry