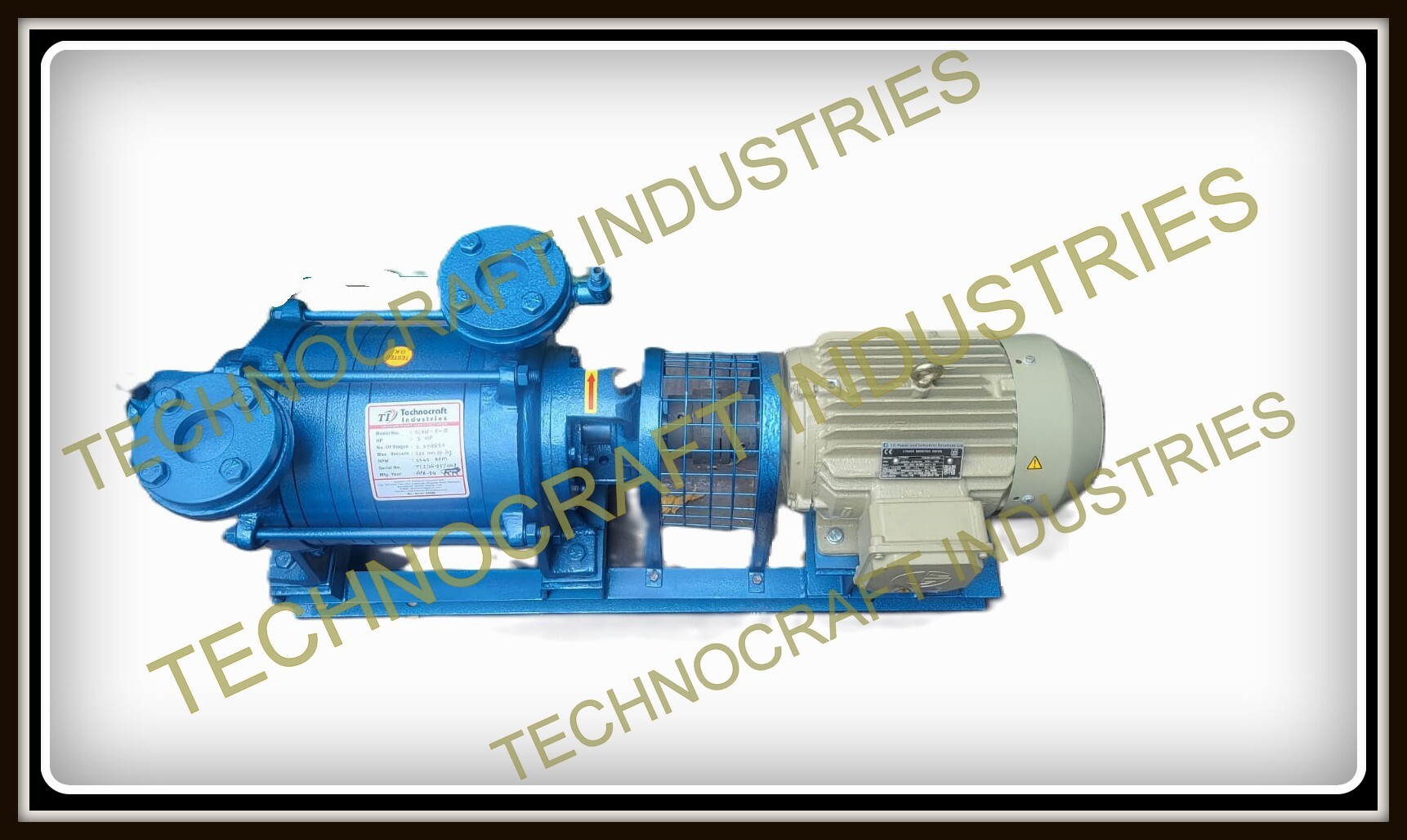

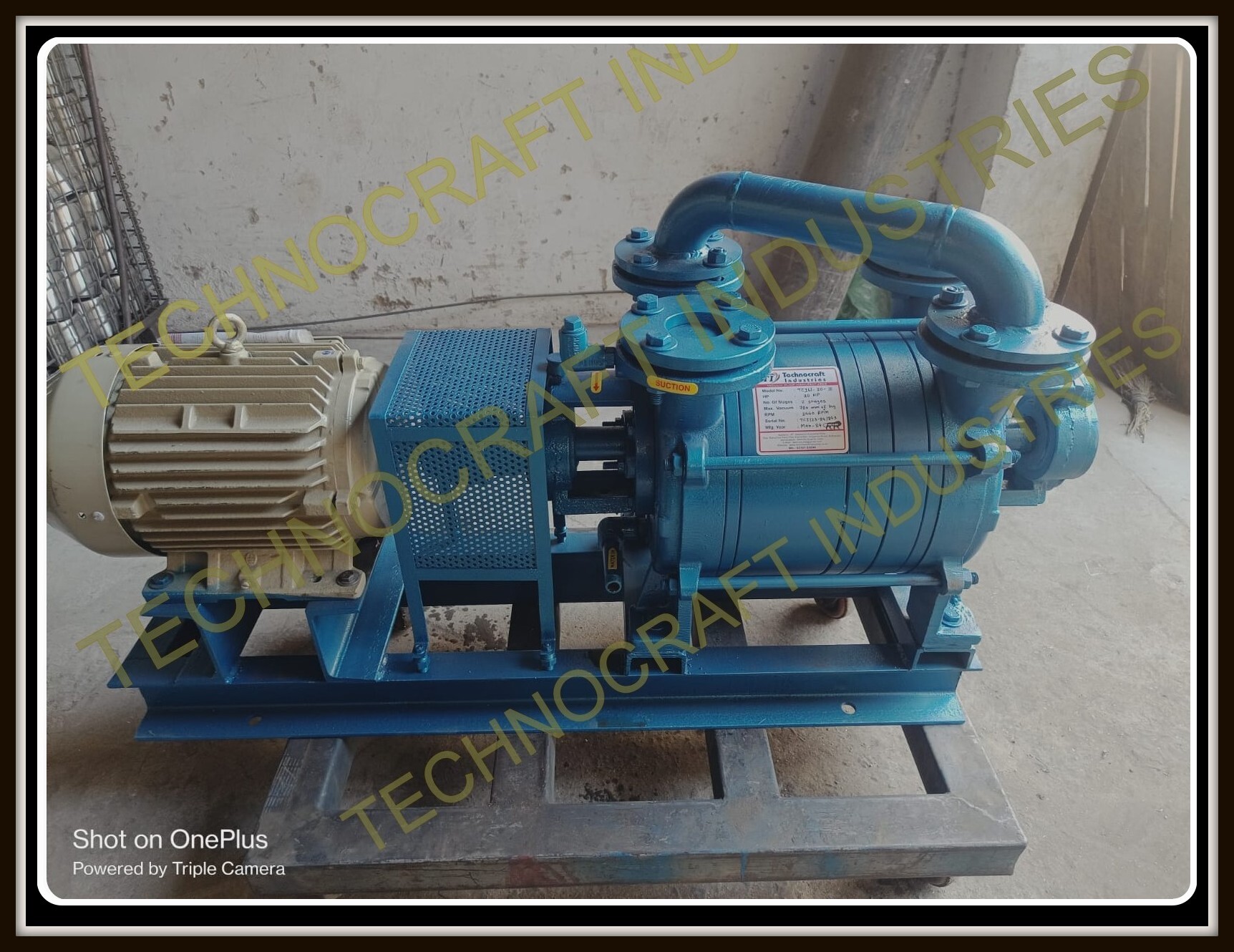

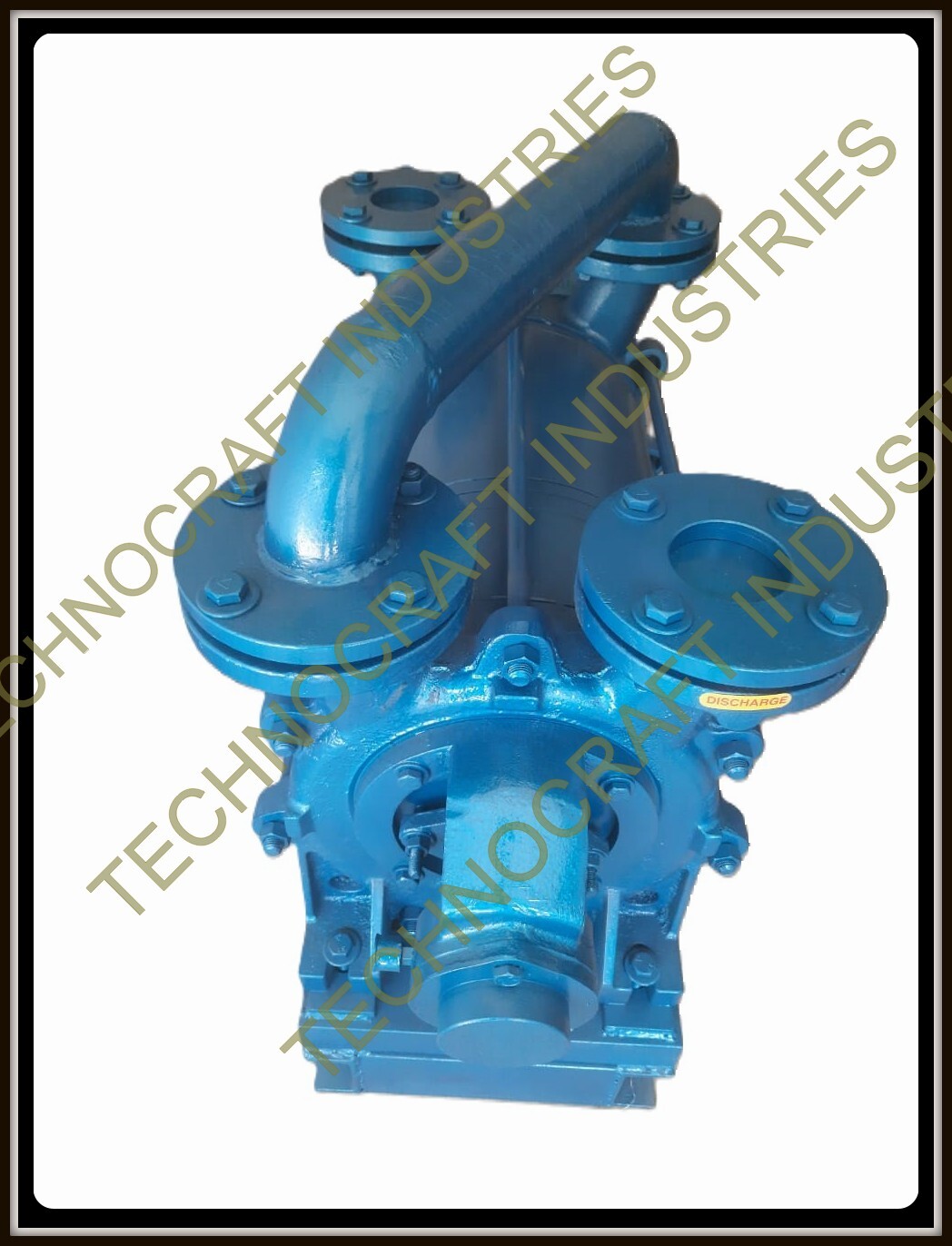

Two Stage Watering Vacuum Pumping System

Two Stage Watering Vacuum Pumping System Specification

- Theory

- Vacuum Pump

- Flow Rate

- 85 m/hr to 1080 m/hr)

- Max Suction

- 720 mm of hg

- Inlet/Outlet

- Standard as per our specific design

- Usage

- Chemical Industry, Pharmaceutical Industry, Sugar & Distillary Industries, Plastic Industries, Packaging Industries, Ceramic Industry, Power Industry, Paper & Pulp Industry, Environment Industry

- Material

- Cast Iron, SS-304, SS-316, Bronze, Gun Metal & as per process requirement

- Size

- Different Available

- Power

- Electric

- Product Type

- Two Stage Watering Vacuum Pumping System, Water ring type vacuum Pump, Direct couple vacuum Pump, Liquid ring vacuum Pump, High Vacuum Pump , ring vacuum Pump

- Color

- Blue

- Seals Type

- Mechanical Seal and Gland Packing

Two Stage Watering Vacuum Pumping System Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD)

- Delivery Time

- Days

- Main Domestic Market

- All India

About Two Stage Watering Vacuum Pumping System

FAQs of Two Stage Watering Vacuum Pumping System:

Q: What industries can the Two Stage Watering Vacuum Pumping System be used in?

A: It is suitable for chemical, pharmaceutical, sugar & distillery, plastic, packaging, ceramic, power, paper & pulp, and environmental industries.Q: What is the maximum suction capacity of this vacuum pumping system?

A: The system offers a maximum suction capacity of 720 mm of Hg.Q: What materials is the system constructed from?

A: The system is made from cast iron, SS-304, SS-316, bronze, and gunmetal, with customization available based on process requirements.Q: What is the flow rate capability of this system?

A: The system has a flow rate range from 85 m/hr to 1080 m/hr.Q: What type of sealing is used in this system?

A: It utilizes mechanical seals and gland packing for enhanced reliability and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Vacuum Pumps Category

Water Ring Vacuum Pumps Two Stage

Price 45000 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron, SS304, SS316, Bronze, Gun Metal & as per process requirement

Flow Rate : 85 m/hr to 1080 m/hr

Power : Electric

Seals Type : Mechanical Seal and Gland Packing

Industrial Two Stage Water Ring Vacuum Pump

Price 40000 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron, SS304, SS316, Bronze, Gun Metal & as per process requirement

Flow Rate : 50 m/hr to 1080 m/hr

Power : Electric

Seals Type : Mechanical Seal and Gland Packing

Vacuum Pump for Macroni

Price 35000 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron

Flow Rate : 50 LPM to 10000 LPM

Power : Electric

Seals Type : Oil seal sealing

Rotary Vane Vacuum Pumps

Price 25000.00 INR / Piece

Minimum Order Quantity : 1 Number

Material : Mild Steel

Flow Rate : 50 LPM to 10000 LPM

Power : Electric

Seals Type : Oil seal sealing