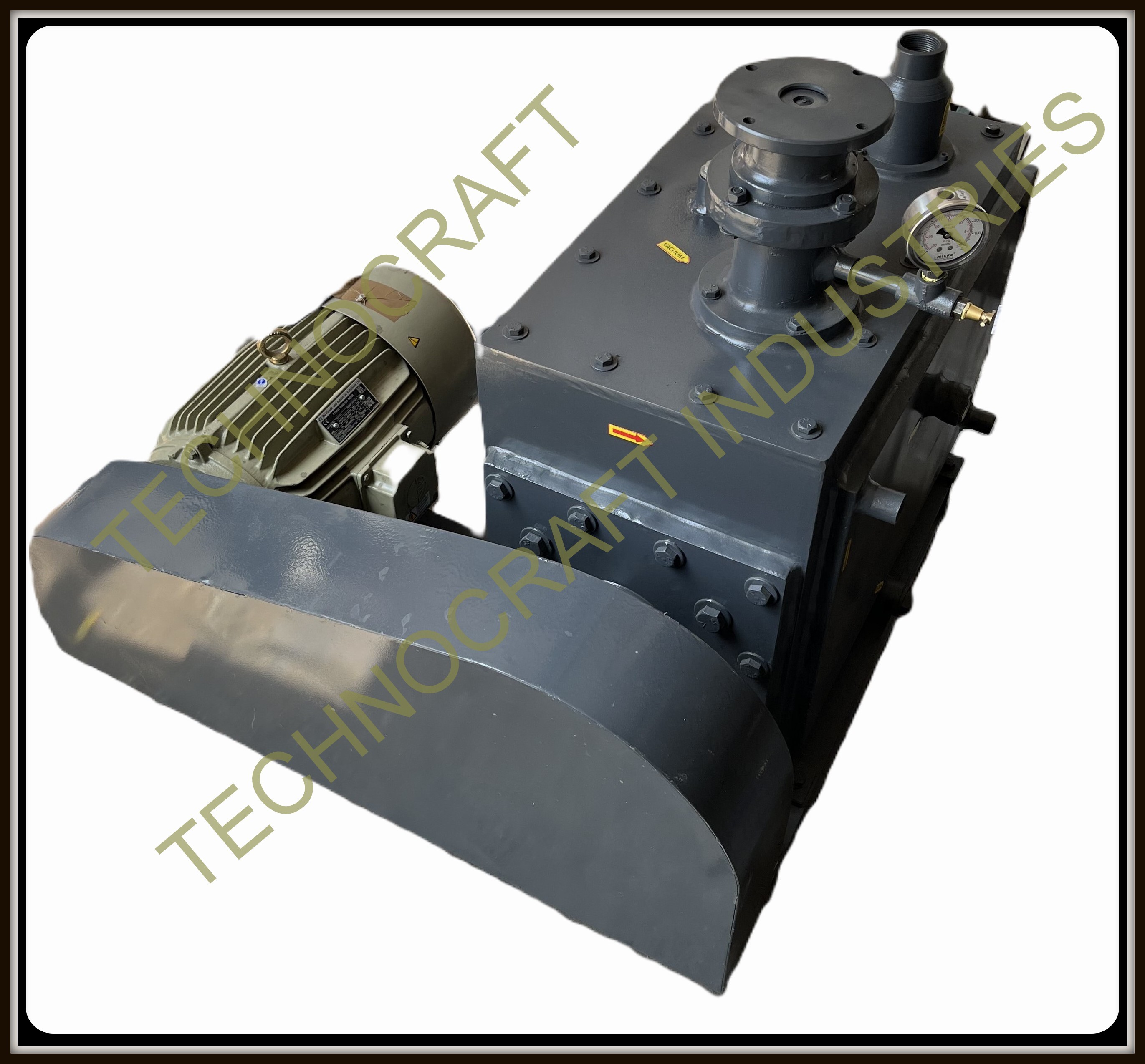

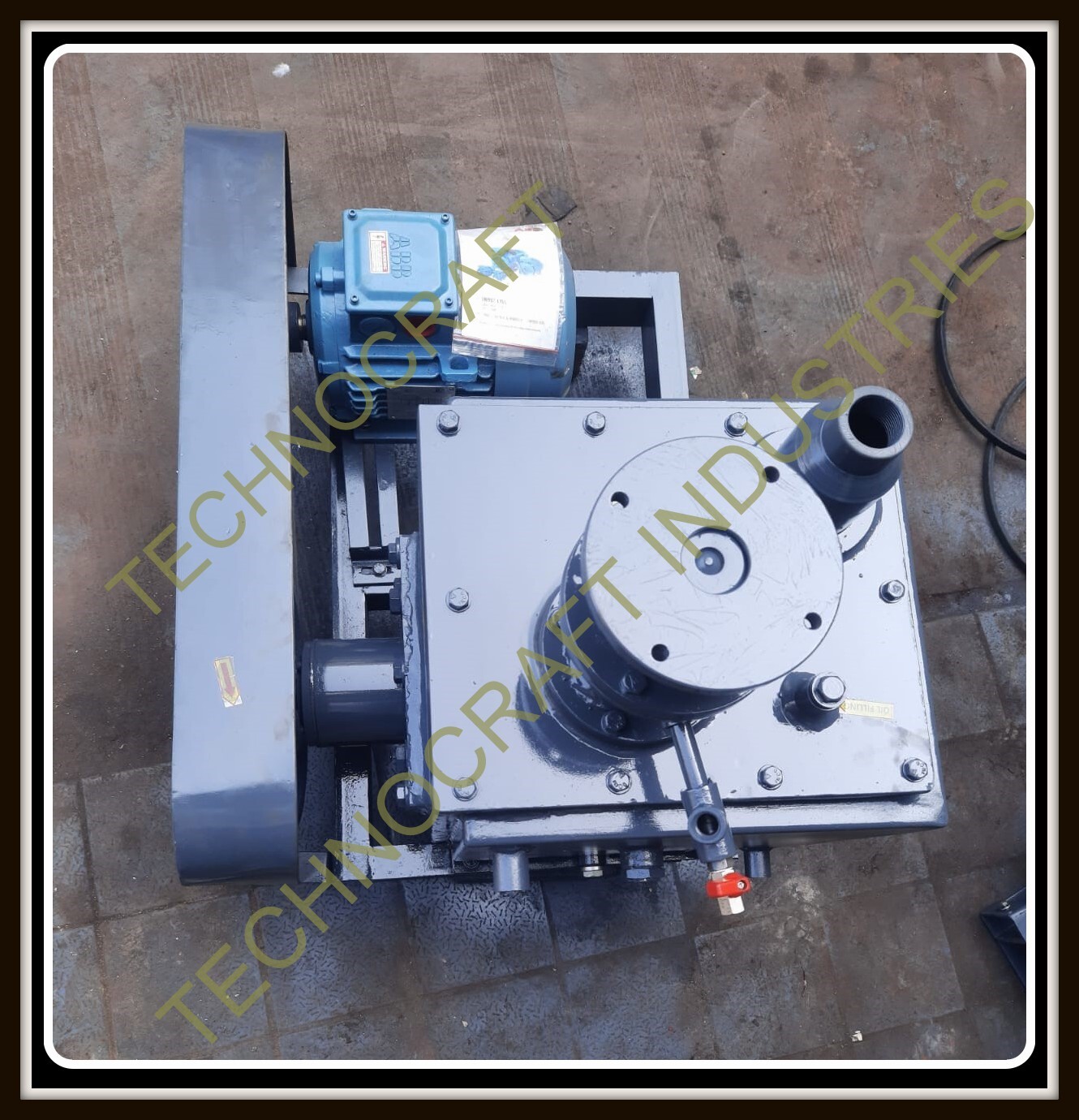

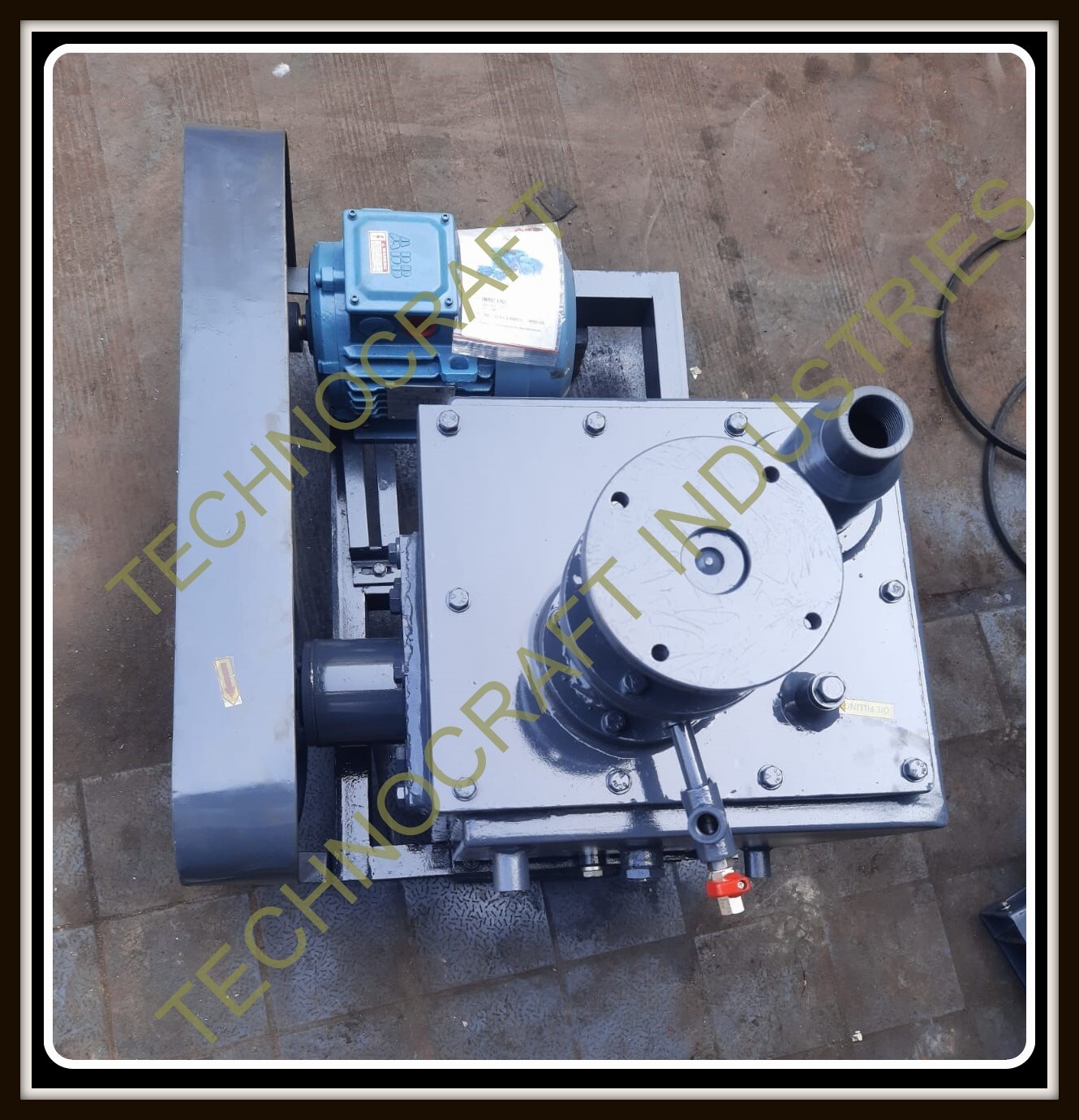

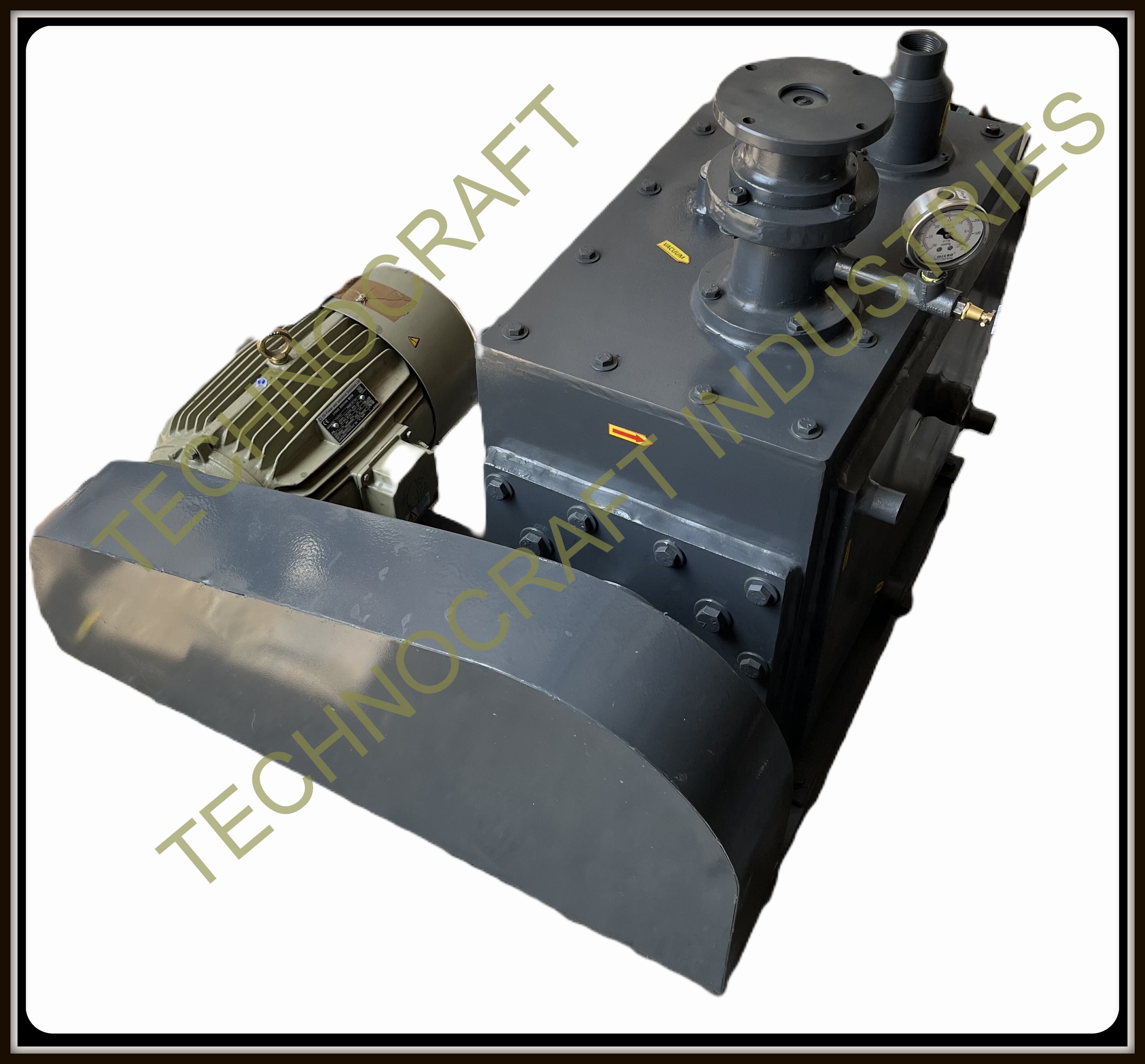

Vacuum Pump For Distillation

Vacuum Pump For Distillation Specification

- Theory

- Vacuum Pump

- Flow Rate

- 50 LPM to 10000 LPM

- Inlet/Outlet

- Standard as per our specific design

- Max Suction

- 760 mm of hg- 0.005 Ultimate Vacuum

- Usage

- Dehydration and Filtration Processes Distillation, Exhausting Electronic Tubes GLS Lamps / Mercury Vapour Lamps & Tubes Sterilizing Vacuum Metallurgy, Vacuum Sublimation Vacuum Impregnation, Thin Film Coating

- Material

- MS

- Size

- Different Available

- Power

- Electric

- Product Type

- Vacuum Pump For Distillation, Oil seal Vacuum Pump, Rotary Vane Vacuum Pump, Rotary Vacuum Pump, High Vacuum Pump, Belt Driven Vacuum pump, Oil Lubricated Vacuum Pump

- Color

- Blue

- Seals Type

- Oil seal sealing

Vacuum Pump For Distillation Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD)

- Delivery Time

- Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Vacuum Pump For Distillation

These are oil - immersed, rotary vane type pumps. The rotor with twospring loaded vanes is mounted eccentric in the stator body. As the rotorrotates, the vanes sweep the crescent shape air space twice in each revolution.There is inbuilt non-return valve which prevents back flow of air. All movingparts are manufactured from graded material. These parts are preciselymachined, ground and assembled with close tolerances which results in increasedefficiency and long trouble free operating life.FAQs of Vacuum Pump For Distillation:

Q: What is the primary application of the Vacuum Pump for Distillation?

A: The Vacuum Pump for Distillation is primarily used for applications such as dehydration and filtration processes, distillation, exhausting electronic tubes, sterilizing GLS lamps/mercury vapor lamps & tubes, vacuum metallurgy, vacuum sublimation, vacuum impregnation, and thin film coating.Q: What are the available flow rates for the Vacuum Pump for Distillation?

A: The flow rates for the Vacuum Pump for Distillation range from 50 LPM to 10,000 LPM.Q: What is the maximum suction capacity of the Vacuum Pump for Distillation?

A: The maximum suction capacity of the Vacuum Pump for Distillation is 760 mm of Hg, achieving an ultimate vacuum of 0.005.Q: What type of seals does the Vacuum Pump for Distillation use?

A: The Vacuum Pump for Distillation uses oil seal sealing for enhanced performance and durability.Q: What material is used to construct the Vacuum Pump for Distillation?

A: The Vacuum Pump for Distillation is constructed using MS (Mild Steel).Q: What are the inlet and outlet specifications for this vacuum pump?

A: The inlet and outlet are designed to be standard as per our specific design requirements.Q: Are there different sizes of the Vacuum Pump for Distillation available?

A: Yes, the Vacuum Pump for Distillation is available in different sizes to cater to various operational needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Vacuum Pump Category

High Vacuum Pump

Price 18000.00 INR / Piece

Minimum Order Quantity : 1 Number

Material : Mild Steel

Seals Type : Oil seal sealing

Color : Blue

Theory : Vacuum Pump

Vacuum Pumps For Electroplating Industry

Price 17000 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron

Seals Type : Oil seal sealing

Color : Grey

Theory : Vacuum Pump

Laboratory Vacuum Pump

Price 18000.00 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron

Seals Type : Oil seal sealing

Color : Blue

Theory : Vacuum Pump

Double Stage Rotary Vane Vacuum Pump

Price 45000.00 INR / Piece

Minimum Order Quantity : 1 Number

Material : Cast Iron

Seals Type : Oil seal sealing

Color : Standard Grey

Theory : Vacuum Pump