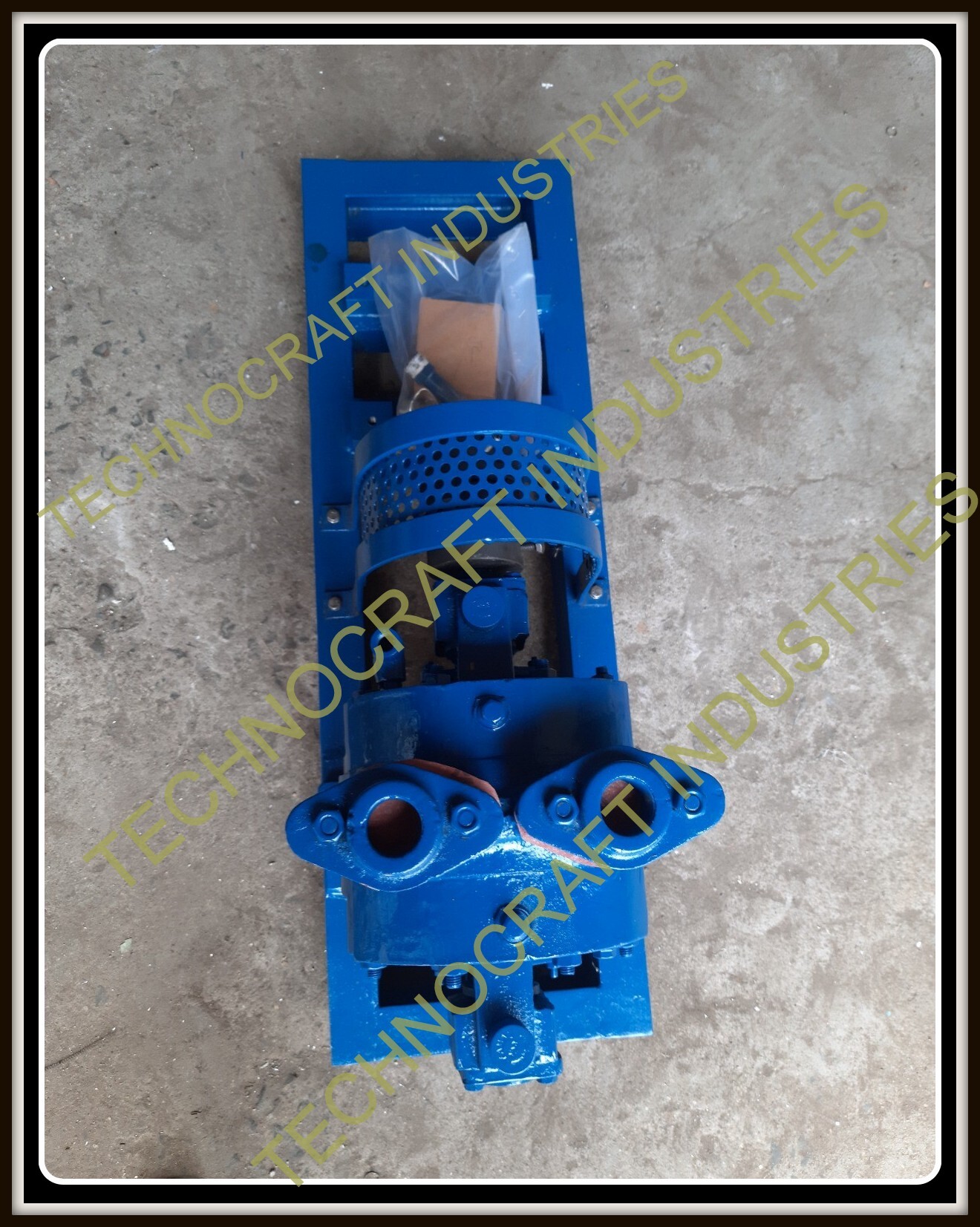

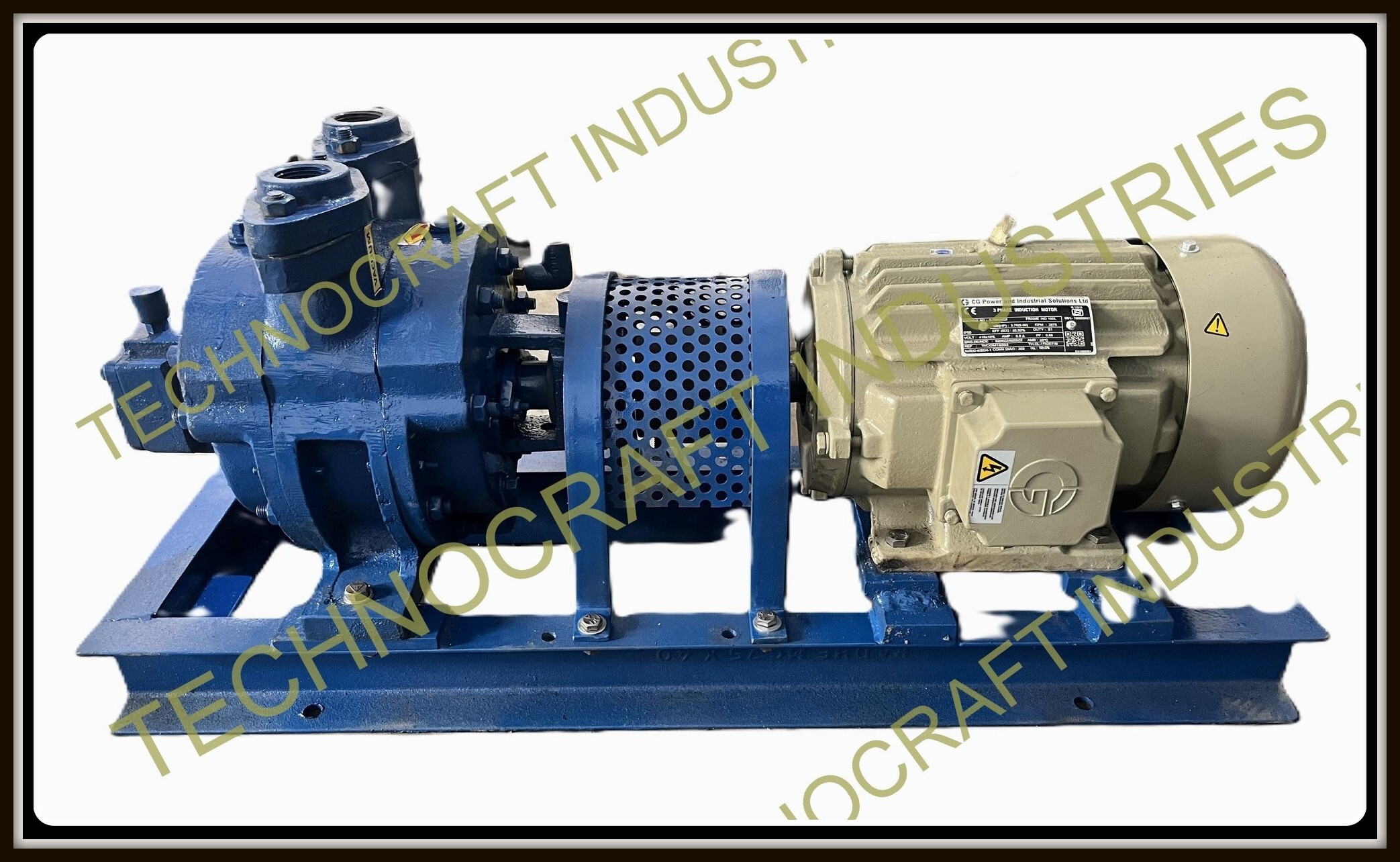

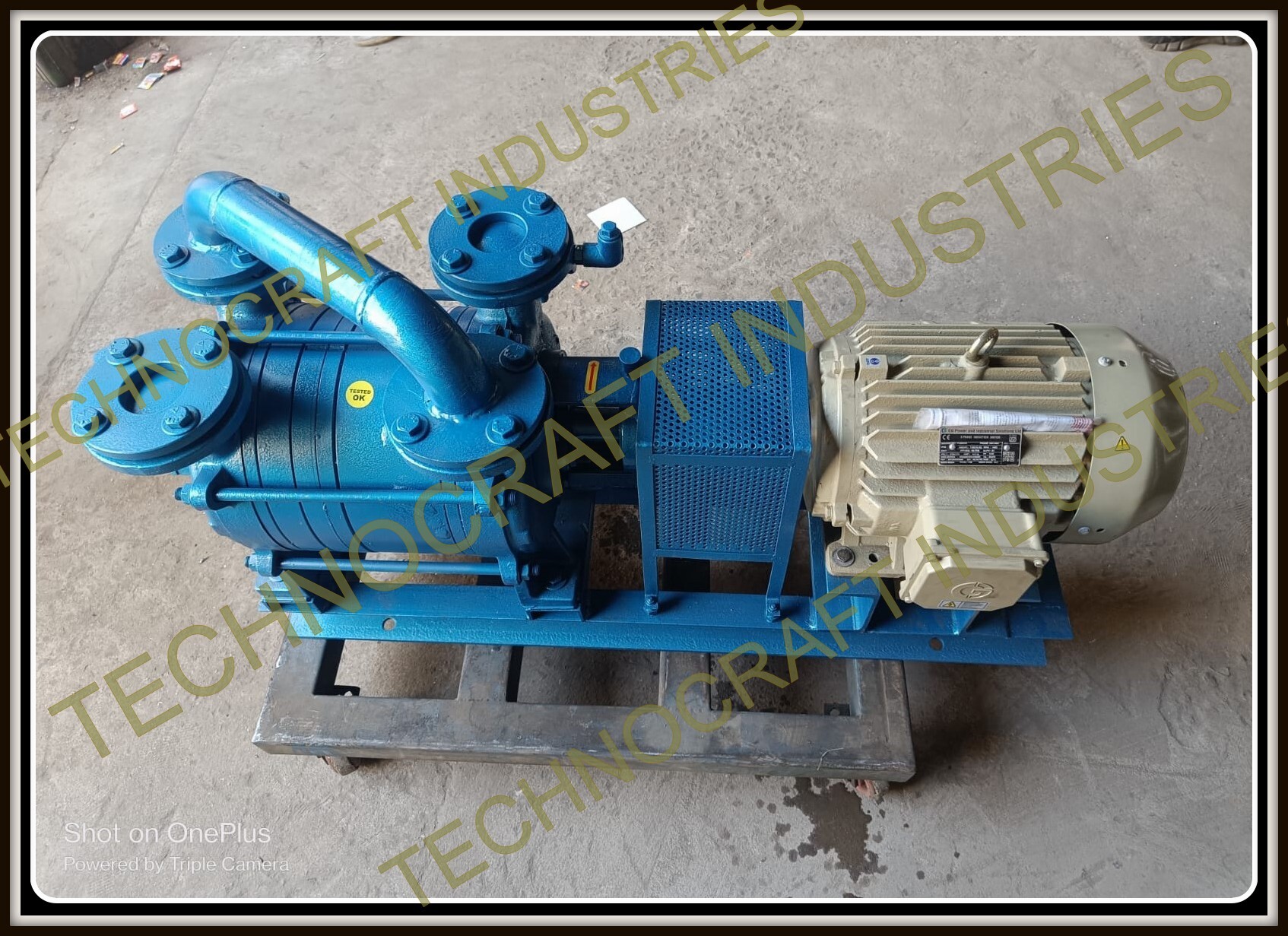

Vacuum Pump For Process Industries

Vacuum Pump For Process Industries Specification

- Inlet/Outlet

- Standard as per our specific design

- Max Suction

- 720 mm of hg

- Flow Rate

- 50 m/hr to 1080 m/hr

- Theory

- Vacuum Pump

- Usage

- Dehydration and Filtration Processes Distillation, Evaporation & Drying Deodorization, Evacuation Sterilizing, Conveying, Venting & Sucking Moisture Extraction, Concentration

- Material

- Cast Iron, SS-304, SS-316, Bronze, Gun Metal & as per process requirement

- Size

- Different Available

- Power

- Electric

- Product Type

- Vacuum Pump For Process Industries, Water ring type vacuum Pump, Direct couple vacuum Pump, Liquid ring vacuum Pump, High Vacuum Pump , ring vacuum Pump

- Color

- Blue

- Pressure

- High Pressure

- Seals Type

- Mechanical Seal and Gland Packing

Vacuum Pump For Process Industries Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Against Delivery (CAD)

- Delivery Time

- Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Vacuum Pump For Process Industries

FAQs of Vacuum Pump For Process Industries:

Q: What are the materials used in this vacuum pump?

A: The pump is constructed using cast iron, SS-304, SS-316, bronze, gun metal, or materials customized as per process requirements.Q: What applications are suitable for this vacuum pump?

A: It is ideal for dehydration, filtration, distillation, evaporation, drying, deodorization, evacuation, sterilizing, conveying, venting, sucking, moisture extraction, and concentration processes.Q: What is the maximum suction capacity?

A: The vacuum pump delivers a maximum suction capacity of 720 mm of Hg.Q: What flow rate does this pump offer?

A: The pump provides a flow rate ranging from 50 m/hr to 1080 m/hr, depending on the model and specifications.Q: What type of sealing system is incorporated in this pump?

A: The pump utilizes mechanical seals and gland packing for effective sealing and leak prevention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil seal Vacuum Pump Category

Oil Sealed Rotary High Vacuum Pumps

Price 15000.00 INR / Piece

Minimum Order Quantity : 1 Number

Flow Rate : 3 cubic meter to 600 cubic meter

Max Suction : 760 mm of hg

Seals Type : Oil seal

Power : Electric

Laboratory Oil Sealed High Vacuum Pump

Price 34000.00 INR / Piece

Minimum Order Quantity : 1 Number

Flow Rate : 3.06 m/hr to 600 m/hr

Max Suction : 760 mm of hg

Seals Type : Oil seal sealing

Power : Electric

Oil Sealed Rotary Vane Vacuum Pump

Price 50000.00 INR

Minimum Order Quantity : 1 Number

Flow Rate : 3.06 m/hr to 600 m/hr

Max Suction : 760 mm of hg

Seals Type : Oil seal sealing

Power : Other

Oil seal High Vacuum Pump

Price 20000.00 INR / Number

Minimum Order Quantity : 1 Number

Flow Rate : 3 cubic meter to 600 cubic meter

Max Suction : 760 mm of hg

Seals Type : Oil seal

Power : Electric